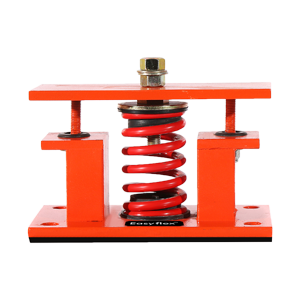

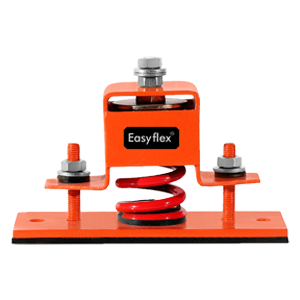

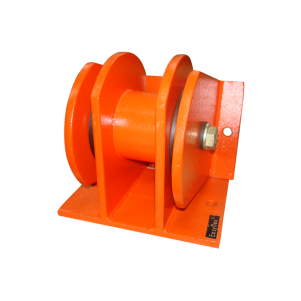

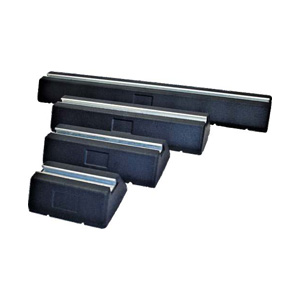

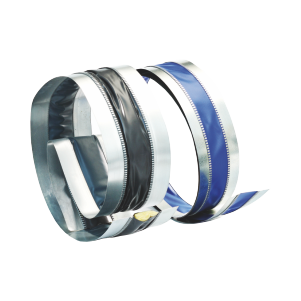

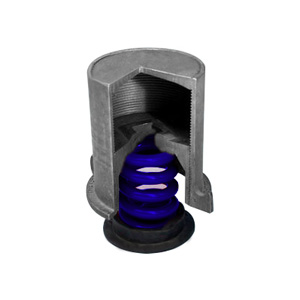

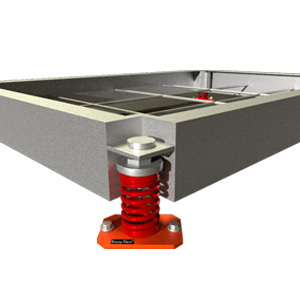

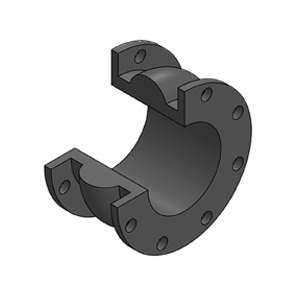

Easyflex Cased Mount isolators consist of high deflection, color-coded stable springs assembled into telescopic cast iron housings which are complete with square cell noise isolation elastomeric pad bonded to the lower and upper load surface and with an adjusting and leveling bolt with a lock nut as a part assembly. Slots are provided in bottom plate in all isolators for bolting to the structure.

Design Features

- Color coded springs to facilitate identification.

- Powder coated springs.

- Load upto 5000 kgs*

- Deflection upto 25mm*

- 4 Models

- 26 Load Ranges

- Deflection is at rated load with 15% Tolerances

- All mounts have approximately 50% overload capacity

- Unique mount design provides horizontal stability, high loading capacity and protective spring enclosure

- All mounts have external leveling arrangement, capable of compensating for full static deflection.

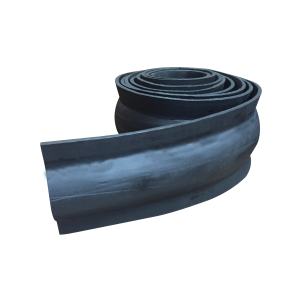

- Inner walls of lower casing have resilient rubber snubbers which;

- Eliminates possibility of binding by providing a smooth guide path for the top casing.

- Limits lateral movement, particularly due to start-up, shut-down and horizontal wind load.

- Prevents isolator short-circuiting by avoiding metal to metal contact.

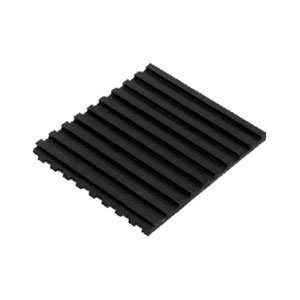

- Neoprene inserts below springs and 6 mm thick ribbed base pad act as noise breaks for high frequencies in the audible range, which can otherwise get transmitted to building structure.

- Mountings must be adjusted so that upper housing clears lower housing by at least 6 mm and not more then 12 mm

Vibration isolators shall be housed springs and shall consist of a steel spring and load cap housed in a cast semi-steel or aluminum assembly, with sponge neoprene snubbers designed to stabilize the isolators and prevent metal-to-metal connection of top and bottom housing sections. The top housing section shall be drilled and tapped and shall include a steel load transfer plate, leveling bolt, and locknut. The bottom housing section shall be bonded to a 1/4 in. (6 mm) thick ribbed neoprene noise isolation pad and shall be slotted to allow bolting to the supporting structure.

Spring elements shall have a lateral stiffness greater than 1.0 times the rated vertical stiffness and shall be designed to provide a minimum of 50% overload capacity.

Springs shall be selected to provide operating static deflections shown on the vibration isolation schedule or as indicated on the project documents. Springs shall be color-coded or otherwise identified to indicate load capacity.

Vibration isolators shall be model EFCS as manufactured by Kanwal Industrial Corporation.

Expert Advice for Your Application

No two Applications are the same. We will be happy to go over your application in detail and discuss the possibility of using this product for your application. Would you like some personal advice or do you have any questions? We look forward to supporting you.

.jpg)

.png)

.png)

.png)