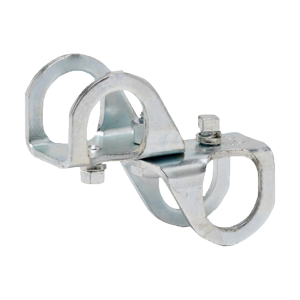

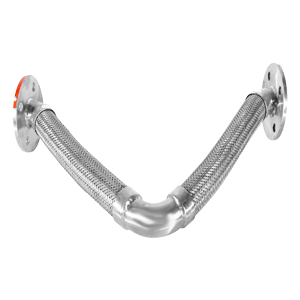

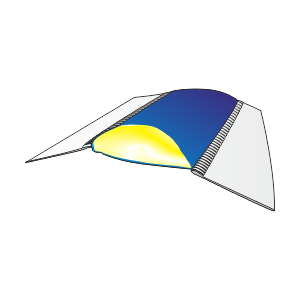

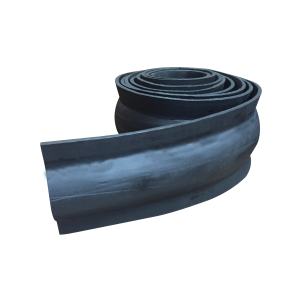

Illustrated below are the typical orientation for the U-Connector. No support is required for the 180º return bend for standard loops 2-1/2” diameter and smaller. However due to the weight of the return bend and the extreme flexibility fo the loop, larger sizes require support to prevent the 180 from sagging in all orientation except when installed hanging down as shown in illustration #2. Guides are recommended but not always required. Special Note - For steam service minimize the entrapment of condensate is crucial and loops should be installed as shown in illustration #1.

Design Features

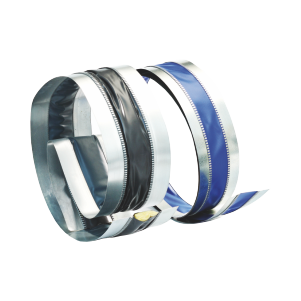

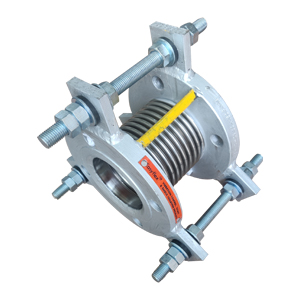

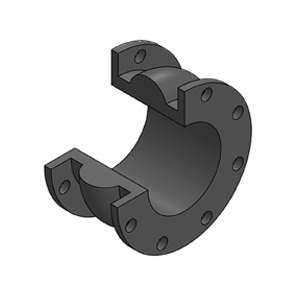

- THERMAL EXPANSION : AXIAL MOVEMENT - The U-Connector is simply a flexible variation of the tradition hard pipe loop. For any given length of pipe and given temperature change, the amount of movement can be calculated and the appropriate U-Connector can be designed. When installed in a pipe run the U-Connector’s legs simply bend laterally to compensate for pipe’s expansion or contraction. Unique to the loop is the incredibly low amount of force required to bend its legs, minimizing anchor loads, guiding and installation costs.

- SEISMIC MOVEMENT : ALL DIRECTION -The two flexible legs connected by an unrestrained return bend, will allow a predetermined amount of pipe movement in any direction. (Typical design movement is ±4 inches in any direction, however movement of several feet in any direction is possible). With the loops extreme flexibility and low force to move, the loop absorbs the seismic energy and imposes minimal loads on the adjacent pipe hangers, supports or nozzle loads on major equipment. See page 11 for more details.

Expert Advice for Your Application

No two Applications are the same. We will be happy to go over your application in detail and discuss the possibility of using this product for your application. Would you like some personal advice or do you have any questions? We look forward to supporting you.

.jpg)

.png)

.png)

.png)